My friend Stephen (Table Tok Games) is making the pilgrimage to UK Games Expo in Birmingham this year and will be running demos of some of the upcoming releases from Hachette Boardgames.

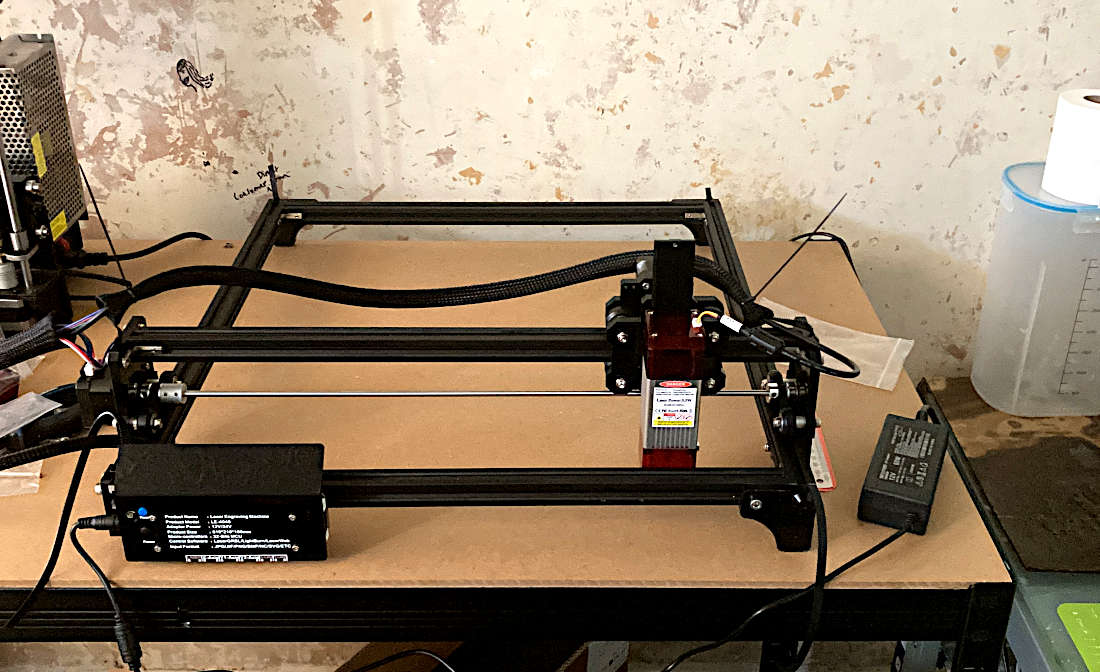

He asked me if I could make some badges for the event. I thought that this would be a great way to learn how to use my new Laser Cutter Engraver.

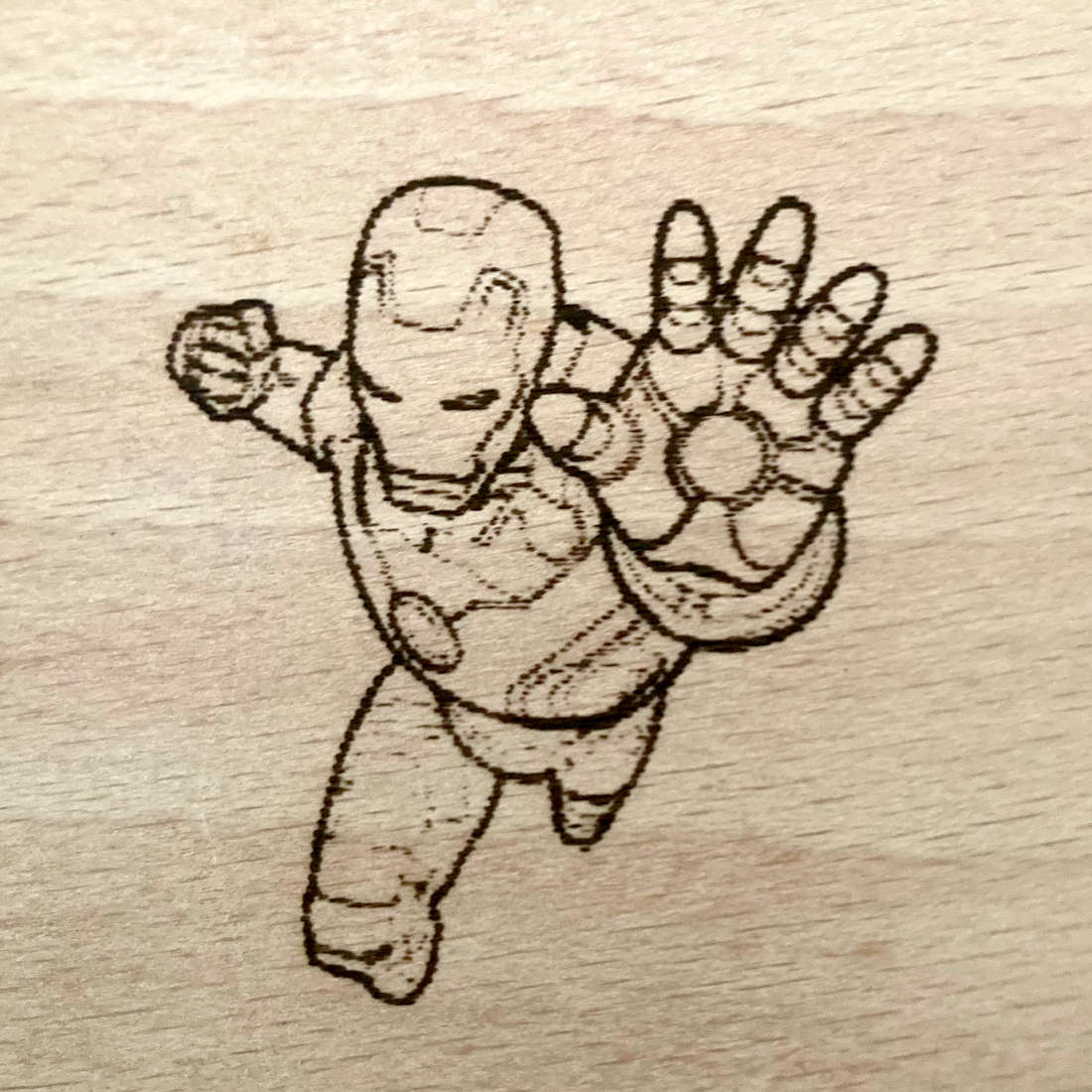

Stephen created a design in two parts, an etch file with his meeple logo and a cut file with a series of 30mm circles which would be the badge. Registration marks in two opposite corners made sure that Illustrator would not trim the images to just the internal drawing.

LaserGRBL

I am currently using LaserGRBL which has support for SVG from inkscape but this is an experimental feature so the files were exported as PNG.

The Cut File

The cut file was uploaded into LaserGRBL and I used the centreline option to vectorize a cut path. This was slightly problematic in that the on the very top and bottom row of circles the line hit the edge of the page and vectorizing broke the cut path.

Pardon the pun, but there is definitely a learning curve when creating files for the laser cutter. The next attempt will have some whitespace between the design and the registration marks.

I imported this at 120mm/min and a laser power of 95%

The Etch file

Importing the etch file I opted to go for the Line to Line Tracing option at a speed of 500mm/min and a laser power of 95%

The Material

I had some scrap MDF sheet left over from some DIY project. This measured 2.8mm thick and I mounted it on my workspace with Duck Double Sided Tape (Boy this stuff is sticky)

Laser Engraving

I was reasonably pleased with the engraving which took just over 20 minutes with one pass. I initially tried 1000mm/min but the laser threw an error about two thirds of the way through and it would not recommence. I think that it must have run into a buffer problem or the speed was too high. I have not done any testing on speeds as yet so this may be part of my learning curve.

The only downside with the Line to Line Trace option is that it prints like a conventional printer and you get jaggy curves (there's no anti-aliasing as far as I can tell)

Laser Cutting

This is where I fall down, hard. With any new technology or tool you just have to learn what works and what doesn't. I have no idea if I am using the software correctly, if my laser is focused correctly, how many passes I should be making, should I be using Air Assist, if my material is at fault or even if I am expecting too much. There are so many variables.

After 4 passes and 160 minutes of cutting I gave up in frustration.

Resin 3D Printer to the Rescue

This job still needed to be completed as delivery is scheduled for the following day. 45 minutes later these bad boys came off the Photon Mono 4K.