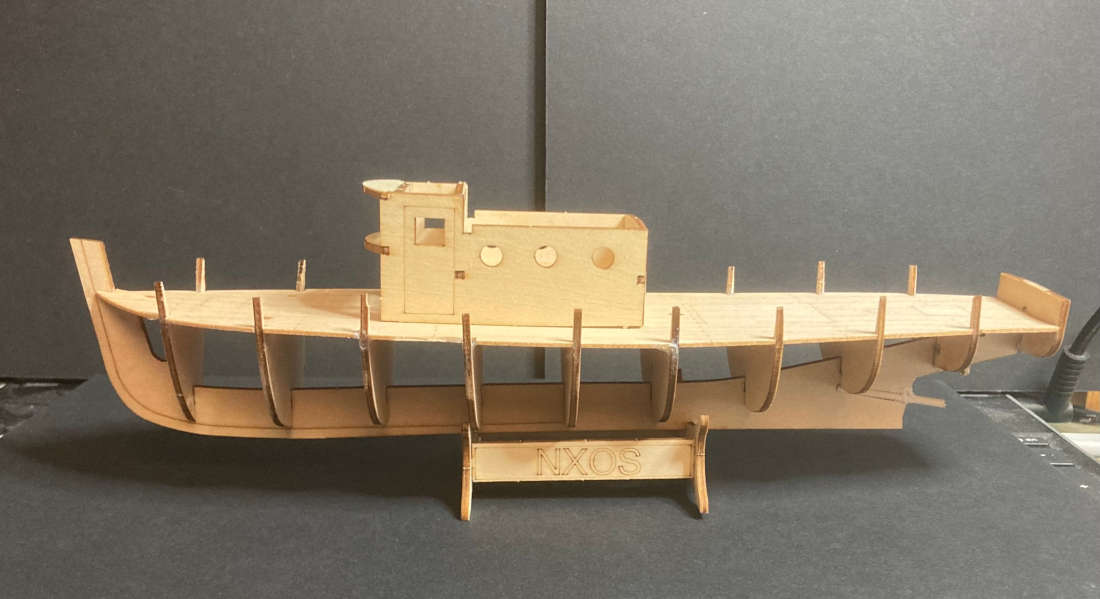

In Part One we got the basic hull together

Sanding and More Sanding

As I mentioned the hull is made of straight ply planks and there are a lot of gaps and seams which require filling with wood filler. I bought a tub of 151 wood filler which I thought was going to do the trick and I was dissapointed that it was more like wall filler than anything else. Still I persevered and ended up slapping on a ton of the stuff.

In hindsight I would do this totally differently. The filler oozed between the planks and ended up inside the boat hull trapped between the frames which then dried and fell off. I have in effect created a boat shaped maraca.

This necessitated opening up the deck under the wheelhouse in order to release the now rock hard filler. This might sound like major surgery, but as the deck is so thin it was easily acomplished with a sharp craft knife and a steady hand. I made sure to keep the offcut as I have plans for that later.

The way to tackle this is to use the old superglue and baking soda trick to fill up the gaps. This of course only works if you are painting the hull. If you are going for the natural wood finish then you are going to have to get better at laying the planks.

Painting

Painting the boat in sections is unavoidable at this stage. I carefully masked off the deck and gave the now smooth (ish) hull a spray coat of white primer followed by a couple of coats of white gloss.

The airbrush then came in handy for painting the decks with a Vallejo Burnt Umber wash.

The remaining wooden pieces for the wheelhouse, deck covers and the gunwhales were then extracted from their boards and sprayed with the same Vallejo Burnt Umber wash.

Adding Some Colour

I imagined the boat a sort of tri-tone with a red top stripe white hull and black or red hull bottom. In the end I just gave it a stripe of red on the sheerstrake plank and continuing around the transom. Masking this off was a tricky exercise as I only had some really nasty cheap painters masking tape. I will have to come back and do some tidying up by hand later.

Trial fitting the wheel house accents and deck hatches really makes the boat come alive.

You might beable to see in the photo above that I managed to glaze all the windows with some clear acetate from some recycled packaging. I glued this in using my now favourite hobby glue UV Resin which I picked up in my Wish Hobby Products 2024 experiment. This stuff is amazing.

Adding the Lights

Last year I picked up some micro LED lights for another project (which I have yet to start). These are incredibly tiny and come pre-soldered onto super thin magnet wire. I quickly soldered a couple of these together with a CR2032 coin cell battery holder and a latching push button and stuffed it into the hole.

I will probably tidy this up with a piece of perfboard at a later date as the circuit is tiddly. I am also undecided if I will add any navigation lights. For the uninitiated this mean a RED LED for the left (Port) side of the boat and a GREEN LED for the right (Starboard) side. I have some 3mm LEDs from another side project but these might be too large, we will have to see. Adding them to the circuit should be no problem and might even add some much needed resistance to bring down the brightness.

The LEDs were then routed up through the floor of the front wheelhouse and up one corner. One LED illuminates the interior and is bonded to the roof with the UV Resin and the other goes outside in front of the cabin as an exterior deck light. I will need to find an appropriately nautical shroud for this exterior light as they are suprisingly bright for their size.

Oh did I forget to mention that I added a salty seadog to steer this fine boat across the treacherous seas?

He is one of the many 3D Printed accessories I covered in part one of this mini series. A fine free model although he is now sealed in his cabin for all eternity as I have glued on the roof and floor.

In the next, and final part of this mini series we will add all the accessories masts and rigging.