In my recent foray into buying modelling supplies from Wish.com I mentioned that I had ordered a little wooden boat kit but that the order got cancelled.

Needless to say, I found a different seller on AliExpress and snapped it up.

This is a fun little kit and my first foray into making a wooden boat with a planked hull. I made a balsa wood sailing yacht from old model engineering plans, decades ago with a lot of help from my dad, but I can't remember if we ever finished it.

The NAX Fishing Boat or should I say NAXOS Fishing Boat

The inspiration for this model is clearly that of a mediterranean coastal fishing vessel of which there are many models. The kit is made by NTKJ Model and sold through various etailers.

This is plenty of inspiration for me to commence making this kit.

Meet the Parts

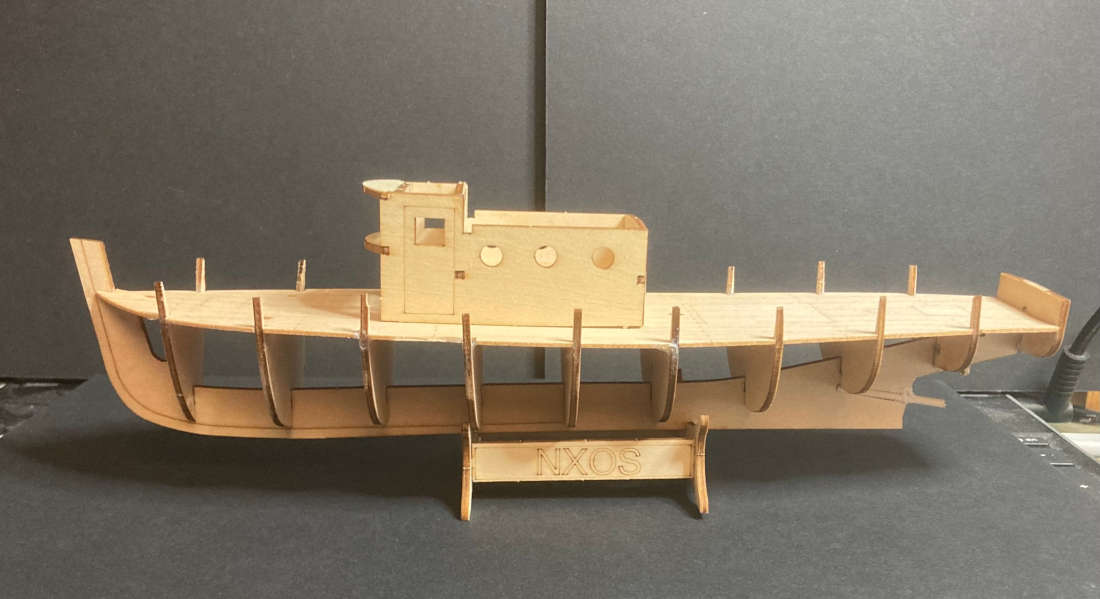

The kit comes as a set of 6 laser cut wooden sheets, a couple of dowels for the mast and a reel of cotton for the rigging. A set of pictorial instructions with quite well translated text completes the package which cost the grand sum of £5.94 which in 2024 money is less than a Big Mac meal.

Steps 1-4 - Making the Deckhouse

Whilst the first 4 parts seem fairly self explanatory and involve removing the deckhouse parts and assembling them, the parts are not numbered. There is a disparity in the plans, in particular the inner bulkhead seems to have a large notch behind it which intimates a part fits into it but the instructions offer no assistance as to what goes in here.

The wheelhouse fits to the deck with 6 pegs and matching holes. Dry fitting the parts to the deck helps keep the wheel house square and stable whilst gluing the instrument panel back wall and the top visor.

I left the roof unglued to enable me to paint the inside and out and to glaze the windows and doors with acetate.

This model is ripe for replacing some of the clumsier laser cut parts with 3D printed ones. In particular the boat has some cowl vents which are made of laminated wood but they look awful and it will be so much easier to find some on the web or even scratch build. The same can be said for the portholes and life preservers.

- Cowl Vents - Cults 3D - A collection of vents of different shapes and sizes. The two large vents at the front of the boat are 20mm tall and the one on the rear of the wheelhouse is 10.3mm tall.

- Life Preservers - Thingiverse - A good looking life preserver model. You will need to print six, two at 10.5mm across and four at 12.5mm across.

- Boat Anchor - Printables - This anchor seems to have the same shape and dimensions as the wooden one. However, the model is huge and will need to be scaled down to fit.

- 3 Bladed Screw - Thingiverse - This will need to print this on a resin printer at about XX scale The original prop is about 11.5mm in diameter.

Steps 5-8 - Laying down the keel

Now the serious work begins. The frames are all numbered and from 1 to 10 and are slotted into their corresponding slots in the keel. Be careful when removing theframes from the sheet as the protruding sections are prone to breaking due to the orientation of the wood grain.

The diagonal slot at the stern of the boat I thought might be for the stern tube but there was no mention of it on the plans. The kit comes with two diameters of dowel. The thin one should be for the stern tube and it is a good idea to add a 1¼ inch length at this point as the keel is relatively thin and likely to snap as you insert the frame 8. Ask me how I know...

You could add the rudder at this point but the stupid thing has one mission in life and that is to snap. It is much better to leave this until after you have planked the hull and either fit it or replace it with a 3D printed part.

Once all the frames are fitted you can add the deck plate. Before you do STOP!

Take the time now to add some cardstock or a thin piece of styrene to the back of the deck plate. It is incredibly thin and the laser engraved planking makes some of the edge planks prone to detatching. The slots that the frames fit in are also too thin and not in exactly the right places for the frames to slot into so you are going to have a whale of a time gently coaxing them into place and you will probably snap a few. Don't panic. Take some time out to put the stand together and have a cup of tea.

The next step is the one I've been both dreading and looking forward to in equal measure.

Steps 7-8 Planking the Hull

That kettle you just boiled is going to be handy. We now need to steam the first couple of planks. These are the wide ones with the little oval holes on the planking sheets marked IV. The holes go at the bow (the front) of the boat and you will need to hold the end of the plank in the hot steam to soften it and then gently put a curve into it.

This is incredibly fiddly so be patient. With these straight planks being made of plywood they really aren't made to go around these curves. I glued 8 planks down from the sheerstrake (the wide one) and then the remaining planks up from the bottom. These all had to be shaped at both ends to fit.

There will be lots of gaps. When we shape the hull planks by sanding we are going to use some wood filler to fill in the gaps. Real wooden boats have caulked seams and they are designed to swell when they get wet and thereby get tighter. The hull is going to be painted so you won't be able to see the seams.

More 3D Printed Accessories

Fisherman with ships Wheel - Thingiverse - I spent a long time trying to find a suitable helmsman for my boat and this one conjurs up the same vibe as the Lovecraftian fishing horror game Dredge. be

To be continued...

Thanks very much for taking the time and trouble to publish this really useful guide/warning to the actual construction. The instructions supplied with the model give a whole new meaning to the word 'minimal'.

ReplyDeleteI've tried one of their models before and you're dead right about the flimsiness of the parts.

This time around I'll adopt a more 'intuitive' approach and in the absence of intelligible instructions, I'll go with my gut.

Thanks again.

Hi, I’ve just bought the same model off Temu. Just to let you know, I had the same problem with the deckhouse, but by a process of elimination, I came across a left over spar that fitted into those 2 grooves. It’s just a flat piece but it’s curved to match that on the double door piece, to assist the roof curve 👍 Thankfully, following your experience, I didn’t glue the larger roof on until near the end of the build. Also if it’s of any use, I used an emery board to widen out the deck grooves prior to glue up and it popped in a treat with no breakages

ReplyDelete